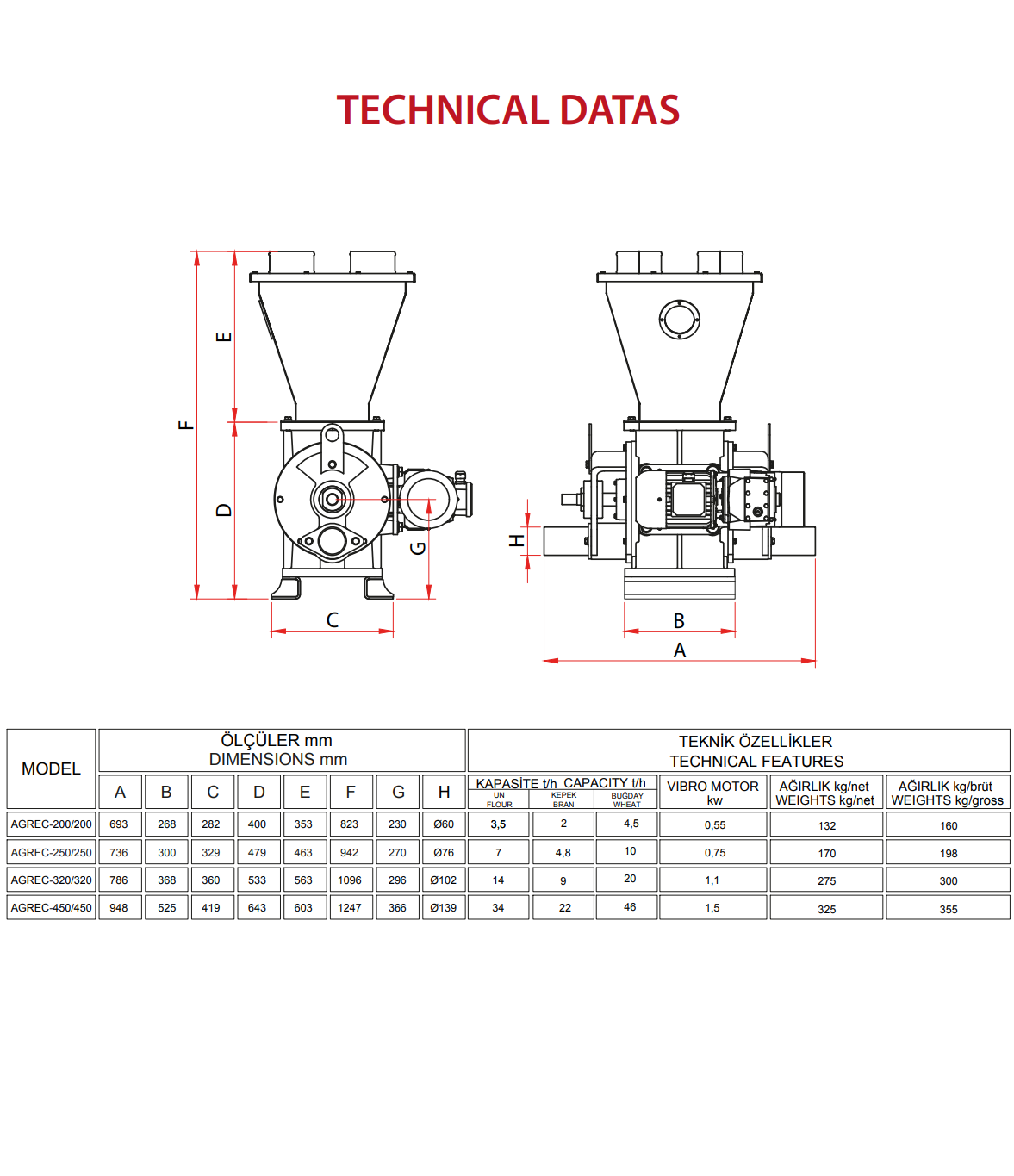

It is specifically designed and manufactured for applications requiring filling and discharging into a pneumatic conveying line. The product coming from the floow throat ensures regular feeding of the inner rotor with the help of a bunker. The final product, filled between the steel winged pockets fixed on the rotor, is transferred to the desired location with the help of compressed air (blower) between 1-1.5 bars. Thanks to the precise and standard tolerances between the body and the rotor blades, compressed air is prevented from leaking into the product inlet, thus ensuring high efficiency and smooth operation. Different models are available for different products and capacities.